|

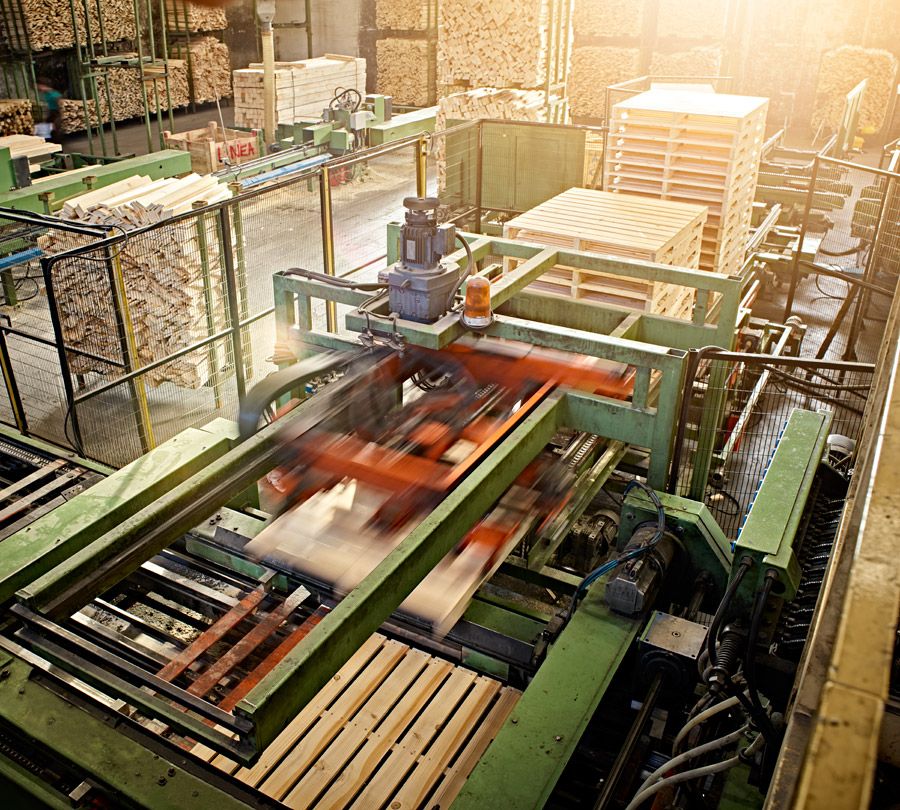

SARTORILEGNO  |

THE QUALITY PRODUCT

|

HEADQUARTERS AND PLANTFONDO |

PLANTMEZZOLOMBARDO |

|

|

HISTORYSartorilegno was founded by Luigi Sartori in 1981 in the village of Fondo in Val di Non, working in some small premises previously used as a cellar owned by his family. His great passion for woodd and his entrepreneurial spirit gave a strong boost to the growth of the company, which, in consequence of strong investments in technology and machinery, has become a national reference point for the entire sector.These are the main stages in the company's history:

Thanks also to the experience acquired over time, Sartorilegno is now on the market as an established reality, able to respond quickly to all customer needs in the field of goods handling.

|

|

SERVICESThe services that Sartorilegno can offer to the customer are designed to ensure excellent functionality with the highest possible cost-effectiveness.

|

|

SARTORILEGNO IN FIGURES30,000sq.m. at Fondo, in Val di Non, of which 6,000 sq.m. are covered

|

|